Understanding the Risks Associated with Industrial Tools

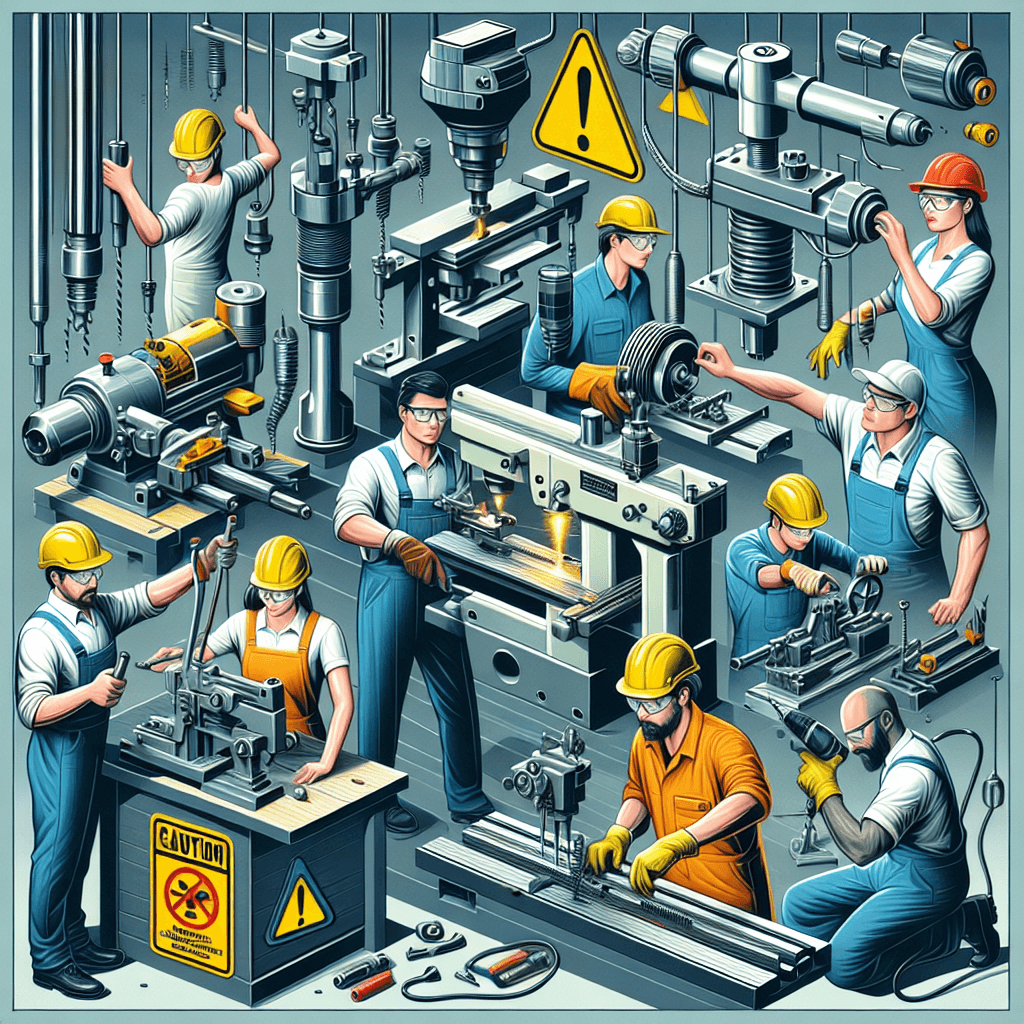

The urgency of understanding the Machinery and Equipment Related Accidents risks related to industrial tools cannot be overstated. A single misstep in handling or improper maintenance can escalate quickly, resulting in severe injuries and even fatalities.

Industrial tools like hydraulic presses, drill presses, lathes, and power saws are all essential for numerous industries, but they are also often the culprits behind workplace injuries. These incidents are not limited solely to physical harm.

They can significantly impair the emotional and psychological wellbeing of the affected individuals, thus emphasizing the need for stringent safety measures and proper handling guidelines.

The detrimental impacts extend beyond the harm caused to the individual. Workplace injuries can induce high costs for industries in the form of penalties, decreased productivity, and rising insurance premiums.

For instance, lack of routine equipment maintenance can lead to tool malfunctioning, not only compromising the product quality but also increasing the likelihood of accidents. Furthermore, accumulated negligence can negatively impact the company’s safety records, thus attracting legal ramifications.

Regular safety checks and intensive operator training are hence indispensable elements of an industrial setup to gauge the associated risks and minimize potential harm.

Preventing Injuries in the Workplace: Key Strategies

In the complex landscape of industrial workplaces, preventing injuries is not a simple task. It requires a systematic approach, with strategies that are tailored to the unique risks and challenges of each setting.

One crucial element of this approach is adherence to safety regulations and standards set by authoritative bodies like the Occupational Safety and Health Administration (OSHA). Rigorous observance of these standards not only helps minimize the risk of accidents but also lends a legal shield to the employers in case of unfortunate events.

It is vital to note that certain industries may have specific regulations, and a detailed exploration of such laws can help in implementing customized safety protocols.

Another significant aspect of preventing industrial injuries is employee training. An industry’s tools and machinery can be complicated and require specialized knowledge for proper handling. Hence, training becomes a key aspect in ensuring that employees operate the tools safely, effectively minimizing the risk of accidents.

Plus, suitable training also allows workers to better understand and respond to accidental situations, thereby limiting injuries. Legal considerations also come into play here, as employers may be held liable for accidents resulting from inadequate employee training.

Provision of regular instructions may also impact the compensation amounts should a claim arise, thus making training a crucial aspect of accident prevention strategies.

The Role of Operator Training in Minimizing Incidents

Effective operator training is pivotal in diminishing the instances of industrial accidents. The proper training equips the operators with the necessary skills to handle industrial tools and machinery safely thereby reducing safety mishaps.

In-depth training familiarizes employees with the characteristics of the tools they handle daily, including any potential risks and the appropriate steps to mitigate them. Operator training extends beyond just handling machinery, it also provides workers with knowledge on how to deal with unexpected situations and emergency procedures.

Nonetheless, the importance of operator training goes beyond reducing accidents. It significantly enhances employee efficiency and productivity. This is because, with proper training, workers understand their roles, responsibilities, and the optimum way to execute tasks. Moreover, trained operators are adept at maintaining their tools, which prolongs the lifespan of these components and ultimately leads to cost savings. Thus, employers should place a premium on offering regular, comprehensive operator training as it is a strategic investment towards a safer, more productive work environment.

Negligence and its Impact on Industrial Safety

Negligence is a persistent issue in industrial safety and often leads to grave incidents, affecting productivity and posing severe health risks to the workforce. The ripple effect resulting from negligence is far-reaching, creating substantial disruptions in the work process and triggering a chain of costly corrective measures. It results in the failure to comply with the established safety protocols, thus leading to avoidable accidents that can cause momentous damage to both human lives and properties. In far too many cases, negligence is the primary factor behind most industrial accidents, contributing to the bulk of workers’ compensation claims.

The consequences of such negligence are wide-ranging, from legal repercussions, financial losses to the detrimental impact on the reputation of the companies involved. Legal complexities often arise in industrial accidents when determining employer liability. This process typically includes a thorough analysis of safety standards, whether the employer adhered to these standards, and if negligence was a contributing factor. Massive compensation amounts are often involved in such cases, primarily determined by specific incident variables. Industrial safety negligence directly affects employers, employees, and even third-party entities such as equipment manufacturers or contractors, underlining the criticality of fostering a robust culture of safety in industrial workplaces.

The Importance of Regular Maintenance and Safety Checks

Undoubtedly, the regular maintenance and safety checks on industrial tools and equipment are the backbone of a secure working environment. These scheduled interventions not only help in identifying wear and tear that often lead to malfunctions, but they also play a crucial role in achieving optimal performance of the machines. Routine checks encompass thorough inspections of the apparatus, replacing faulty parts and running tests to ensure the operational efficiency of the equipment. Timely detection of potential issues can prevent catastrophic failures, unplanned shutdowns and, most importantly, work-related injuries or fatalities.

Dealing with industrial tools implies not only knowledge and skill, but also a high degree of responsibility for ensuring a safe workspace for all personnel. While the role of operators is essential in handling the equipment correctly, machinery maintenance is pivotal. Therefore, safety checks should be conducted systematically, following detailed protocols tailored for each type of machinery. Regular maintenance not only extends the life cycle of industrial tools but also creates a work environment that upholds safety regulations and fosters confidence among employees that their well-being is a priority. Hence, in an industrial setting, prevention through regular maintenance and safety checks is certainly better, and less costly, than cure.

Common Injuries Caused by Incorrect Handling of Apparatus

In the field of industry and manufacturing, common injuries are a pressing issue caused by the incorrect handling of apparatus. This might include instances where workers are not given proper training on how to operate machinery safely, resulting in preventable mishaps. Numerous types of trauma can result from these errors, such as musculoskeletal disorders from poor ergonomics or manual-lifting practices, puncture wounds from mishandling sharp tools, and traumatic injuries like fractures, dislocations, or amputations from mishaps with high-powered machinery.

Notably, blindness or severe ocular damage is also a frequent consequence of mishandling industrial apparatus. This typically occurs when workers neglect to use eye protection or use the wrong type for their task, leading to exposure to harmful substances or sharp fragments. Similarly, hearing loss from chronic noise exposure in industrial environments is a common but often overlooked injury. The human body is not built to endure the constant, high-decibel noise typical of many industrial settings, and long-term exposure without proper precautions can lead to irreversible hearing damage. The implications of these injuries on worker productivity and overall quality of life are immense, highlighting the need for increased attention to correct apparatus handling practices.

Effects of Industrial Incidents on Employee Health and Productivity

Industrial incidents pose a significant threat to employee health, often leading to both short-term and long-term health complications. Workers who are exposed to hazardous conditions or dangerous machinery are highly susceptible to injuries such as burns, fractures, lacerations, and hearing or eyesight damage. Chemical exposure can also lead to severe health conditions including respiratory ailments, skin disorders, and in extreme cases, cancer. These health related issues not only cause personal suffering, but also create a financial burden due to medical expenses and potentially result in loss of income.

The subsequent impact on productivity within the industrial sector is notable. Workers dealing with health issues tend to have lower performance levels and more sick days, which directly affects output. The chronic nature of certain conditions can also lead to prolonged absence or the need for reduced duties. Beyond this, industrial incidents can create a psychologically unsafe environment, leading to a negative impact on the morale and motivation of workers. Moreover, the cost of training replacements, potential litigation, and raised insurance premiums provide additional, quantifiable reductions in the productivity of an industrial organization.

Safety Policies and Regulations in Industrial Settings

Industrial safety in workplaces revolves around a complex network of policies and regulations, tailored to control and prevent the occurrence of accidents. These regulations, which can be both national and international, originate from diverse authorities including Occupational Safety and Health Administration (OSHA), Department of Labor, and other regulatory bodies. They cover a variety of topics, such as appropriate use of machinery, mandatory safety training for employees, regular equipment maintenance, and hazardous waste disposal protocols. These policies not only provide a blueprint for safe work practices but also hold employers accountable for failing to ensure a safe work environment.

One significant aspect of these policies is the emphasis on mandatory training for operators handling hazardous machinery or equipment. Such trainings are considered essential in reducing the incidences of accidents and injuries in the workplace. Moreover, policies require strict adherence to regular maintenance and safety checks. This is crucial as equipment malfunctions are a frequent cause of industrial accidents. Similarly, regulations also stipulate specific standards for the use and disposal of harmful substances, aiming to minimize the risk of chemical exposure and related health complications for workers. By following these directives and nurturing a safety-conscious culture, industries can condense the incident rate, creating a harmonious environment that boosts productivity and morale.

Case Studies: The Aftermath of Industrial Incidents

In one particular case, an employee of a metal fabricating company sustained third degree burns due to a lack of safety measures in the handling of molten metal. Despite wearing appropriate protective gear, substandard equipment resulted in the metal overflowing and causing the accident. This incident led to long-term physical and psychological trauma, and a significant drop in the company’s productivity due to increased wariness among the remaining employees. As a result, a comprehensive lawsuit was filed against the company, arguing negligence. The case wrapped up with a substantial compensation settlement for the victim.

Meanwhile, in a chemical processing facility, an operator was seriously injured due to a sudden reactionary explosion. Upon investigation, it was revealed that the operator was inadequately trained to handle such a situation. Legal consequences were severe for the company as they were not able to effectively demonstrate their commitment to safety regulations and operator training. Beyond these immediate impacts, the incident also triggered a series of changes in safety policies and regulatory guidelines across the chemical industry. This case has been frequently referred to in subsequent industrial accident-related litigations, underscoring the importance of operator training in minimizing risks.

Promoting a Culture of Safety in Industrial Workplaces

Industrial workplaces encompass a plethora of machinery and tools, elevating the threat of dangers and hazards. Promoting a culture of safety stands as a vital aspect of corporate accountability. An effective measure for cultivating a safe environment is rigorous operator training. Thorough training empowers workers with the knowledge and skills necessary to correctly handle industrial apparatus, substantially reducing the likelihood of human-induced mishaps. Overlooking this crucial element, either due to negligence or cost considerations, often backfires, leading to accidents that can severely impair worker health and have lasting impacts on overall productivity.

Simultaneously, regular maintenance and frequent safety checks of machinery and tools take pole position in safeguarding employees. These indispensable routines identify and resolve seemingly minor issues before they metamorphose into significant problems causing grave accidents. A well-maintained inventory of apparatus not only prevents injuries but also lengthens the lifespan of machinery and promotes optimal operational efficiency. The efficient functioning of machinery significantly curtails the downtime employees might otherwise spend on fixing sudden malfunctions, further contributing to productivity. By fostering a culture of safety, industries can ameliorate workplace dangers and considerably elevate the well-being and performance of their workforce.

What are some of the risks associated with industrial tools?

Some of the risks associated with industrial tools include injuries from sharp edges, burns from hot surfaces, exposure to harmful substances, and accidents due to equipment failure or misuse.

How can we prevent injuries in industrial workplaces?

Preventing injuries in industrial workplaces involves various strategies such as ensuring proper operator training, regular maintenance and safety checks of equipment, implementing safety policies and regulations, and promoting a safety culture.

What role does operator training play in minimizing incidents?

Operator training plays a significant role in minimizing incidents by ensuring workers have the necessary knowledge and skills to safely operate industrial tools and equipment. It also helps them understand the potential risks and how to react in case of an emergency.

How does negligence impact industrial safety?

Negligence significantly impacts industrial safety as it can lead to mishandling of equipment, failure to follow safety procedures, or ignored maintenance schedules, resulting in accidents or injuries.

Why are regular maintenance and safety checks important?

Regular maintenance and safety checks are crucial to ensure that all equipment is in good working order, preventing incidents caused by machinery malfunction or failure.

What are the common injuries caused by incorrect handling of apparatus?

Common injuries from incorrect handling of apparatus might include cuts, burns, fractures, and in severe cases, amputations or fatalities.

What are the effects of industrial incidents on employee health and productivity?

Industrial incidents can lead to physical injuries, long-term health issues, and mental trauma. This not only affects the individual’s health, but also impacts their ability to work effectively, leading to decreased productivity.

What are some safety policies and regulations in industrial settings?

Safety policies and regulations in industrial settings can include guidelines on proper use of equipment, procedures for handling hazardous substances, emergency response plans, and requirements for personal protective equipment.

Can you provide any case studies related to the aftermath of industrial incidents?

The article does not provide specific case studies. However, it mentions that industrial incidents can lead to serious consequences, including injury, loss of productivity, and legal repercussions.

How can we promote a culture of safety in industrial workplaces?

Promoting a culture of safety can be achieved through education and training, implementing and enforcing safety policies, regular inspections and maintenance, and encouraging employees to report any safety concerns or incidents.